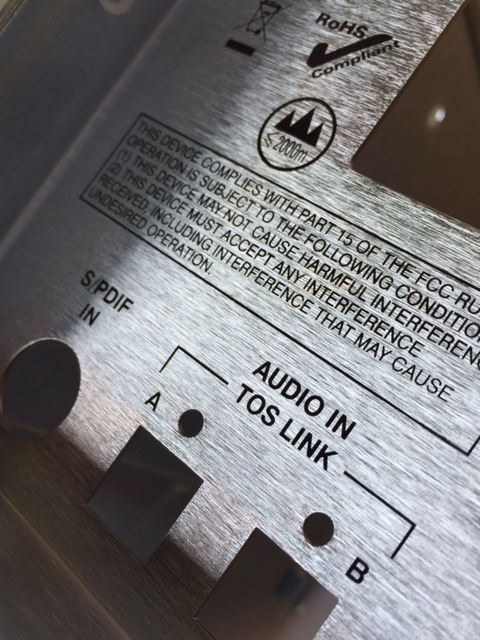

Metal Plating

Sheet Metal Plating

Working with a variety of materials, we can tailor our metal plating process to meet the needs of a wide range of clients. So whatever the scale or timeframe of the job at hand, you can be sure that we will be able to help you.

Metal Plating Process

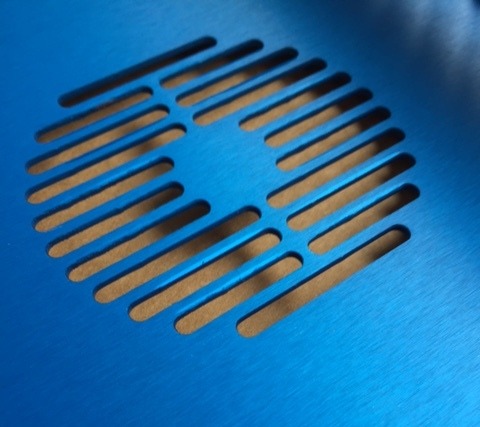

We offer a variety of different services to our clients. Currently, we are able to work with surtec, zinc and clear, iridite, nickel, and tin. So no matter what kind of finishing you are looking for on your product(s), we will be able to work to meet your exact specifications. If it’s anodising metal plating you are interested in, then you will be pleased to know that we can offer a full range of colour anodising as well as clear anodising here at LL Potters.

Your plating options can be further enhanced by corrosion protection and/or decorative grained finishes.

We’re Here to Answer Your Metal Plating Questions

Of course, if you aren’t sure which kind of metal plating would be correct for your particular application, please reach out to a member of our team today. With years of experience under their belts, they will be able to identify what it is that you are looking for, and then point you in the right direction. That’s why we’re the company people come back to time and time again!

Contact Us Today

Our prices are competitive, and we are able to work to a variety of deadlines. So if you want to find out more about metal plating services and how they could benefit your project, please do get in touch with us today. We’ll be able to get the ball rolling as quickly as possible.

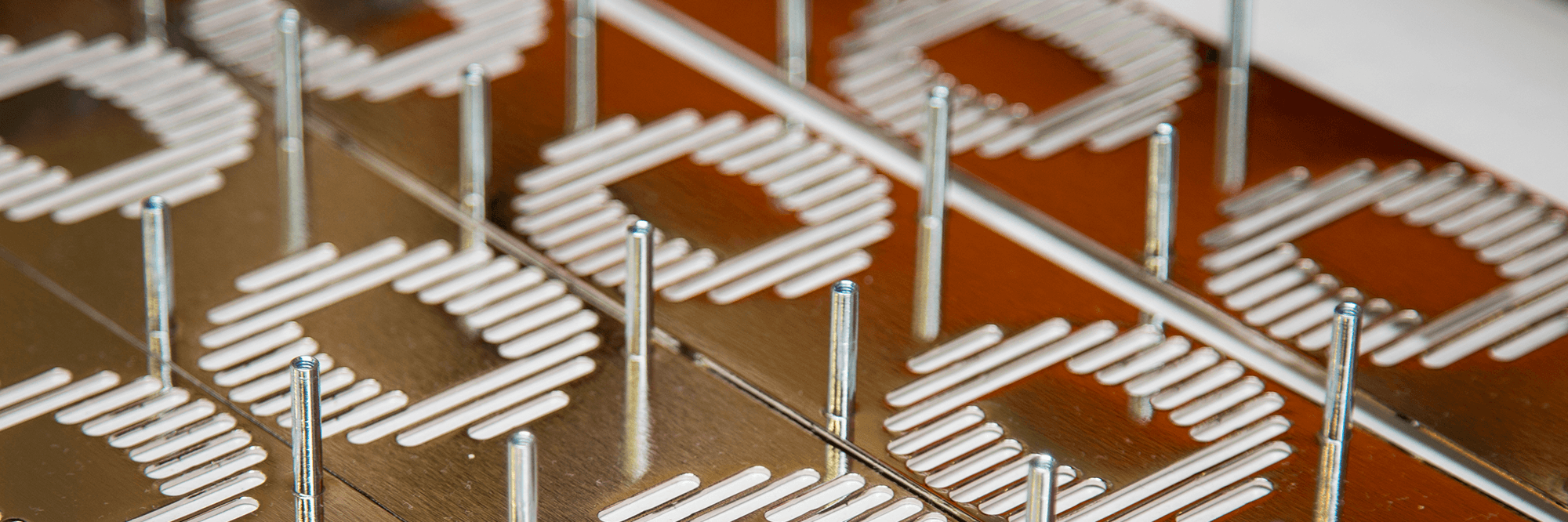

Full range of plating available including:

- Alocrom 100, 1000 and 1200

- Anodising

- Black Tin

- Iridite NCP

- Nickel

- Surtec 650

- Zinc and clear

How is metal plating done?

Metal plating is most commonly performed by immersing the metal in an acid solution with an anode electric current and cathode. The electricity causes negatively charged ions to move to the anode and positively charged ions to move to the cathode. This then covers the metal part in an even coating of metal. Metal plating often sees a lighter, lower-cost metal coated in a thin layer of more expensive metal such as nickel or zinc.

If you want to find out more about the process that we use, we would love to answer any further questions that you may have.

What types of plating are available?

We are here to offer our customers as much choice as possible, and you can take your pick from various different kinds of metal plating when you work with us. Here at Potters, we are able to offer Surtec, Zinc & Clear, Iridite, Nickel, Tin and various colours of Anodised plating finishes.

Each kind of metal plating has its own unique benefits, and will be suited to a specific range of applications. To make sure that you are choosing the correct metal plating for your project, we will be on hand to offer support and point you in the right direction.

Why is it important?

Why is metal plating important? Well, it allows you to introduce the qualities of a specific kind of metal to your particular part.

In addition, the lifespan of metal components without plating can be significantly reduced.

Metal plating adds a layer of non-corrosive and/or high-shine material to the surface of the metal substrate, making it much more resistant to rust, corrosion, and wear.