PLANT AND EQUIPMENT LIST

General Information

ISO 9001: 2015 Accreditation

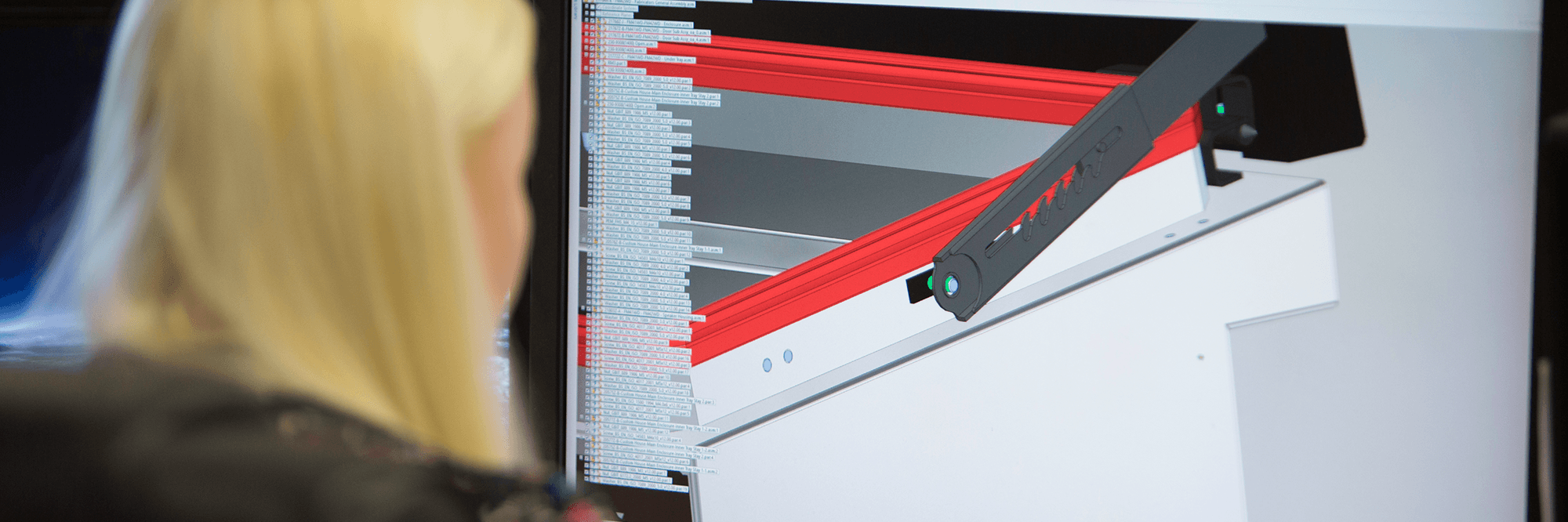

Solid Edge 3D Modelling

Amada Dr ABE blanking and nesting software

Metalsoft blanking software

Mietrak Bar Coded Manufacturing and MRP system.

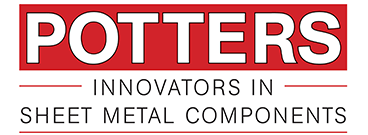

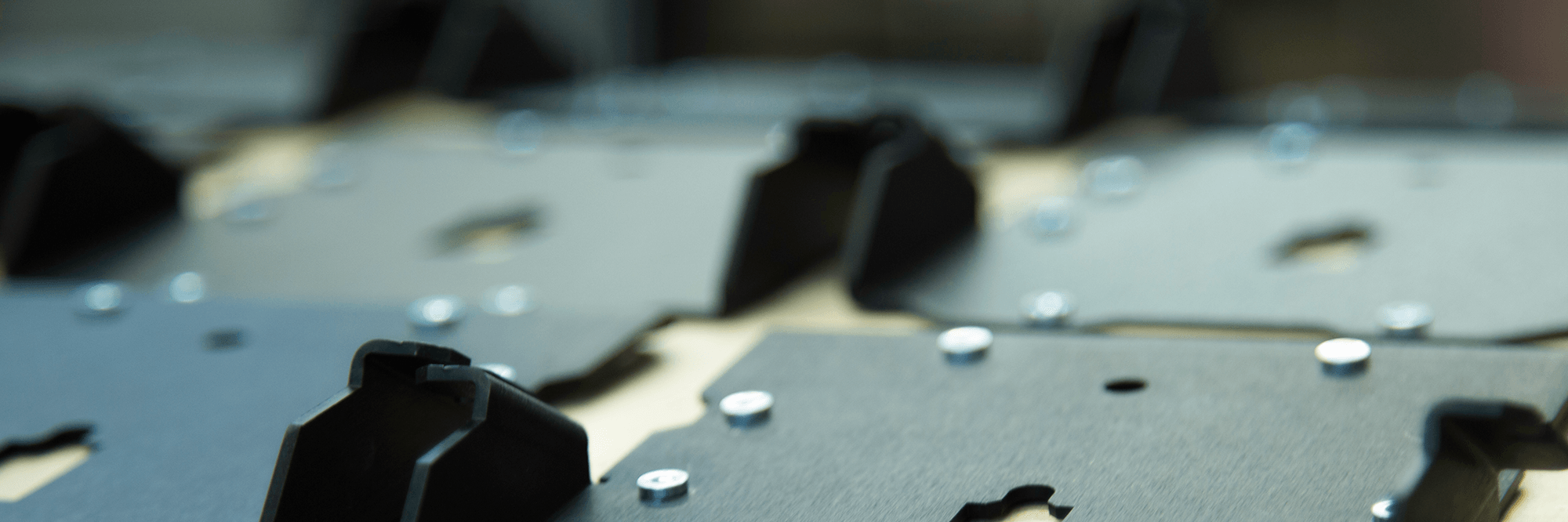

Laser & Punching

Amada EML-AJ Combination Fibre laser/punch Machine with automatic sheet loading/unloading

Amada Togu-3CE Tool sharpener

Extensive inventory of stock tooling

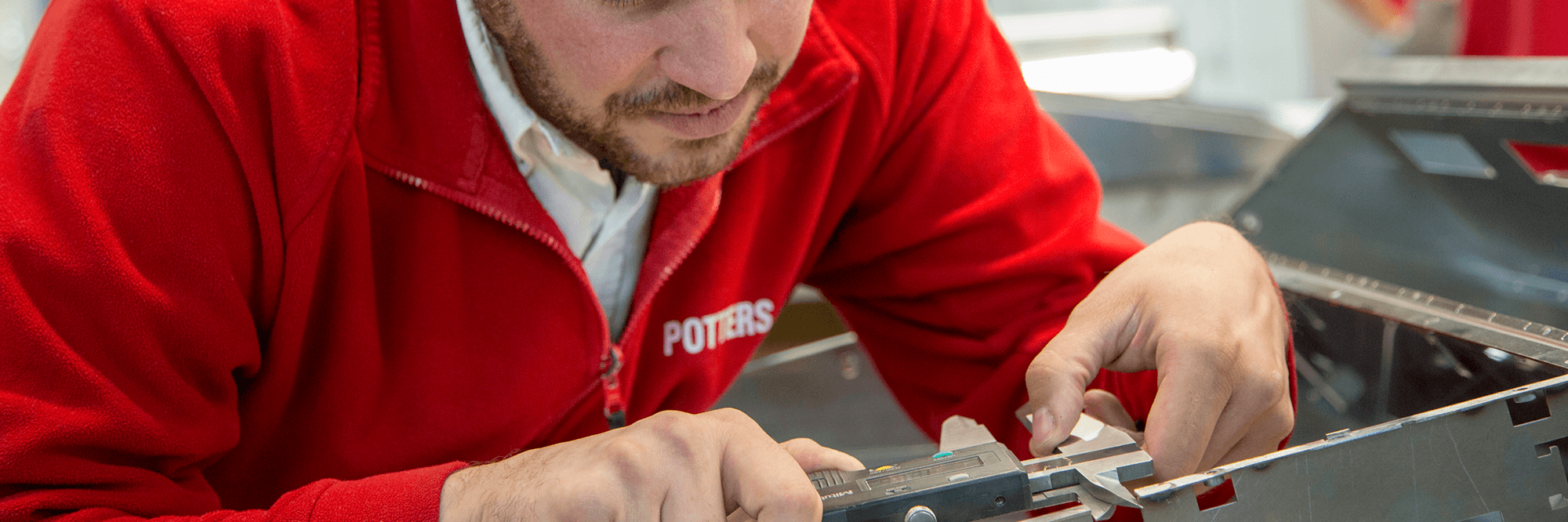

Inspection

Virtek Laser scanning machine

Deburring

1 x TimeSaver 42RB 1350mm Rotary Brush Deburrer

2 x Vanco Deburring machines

Graining

1 x Time Savers 2200 Series 900mm

1 x Conveyor Grainer

Additional cutting

Amada Guillotine

Amada Corner Notcher

Shot blasting

1x Shotblasting unit

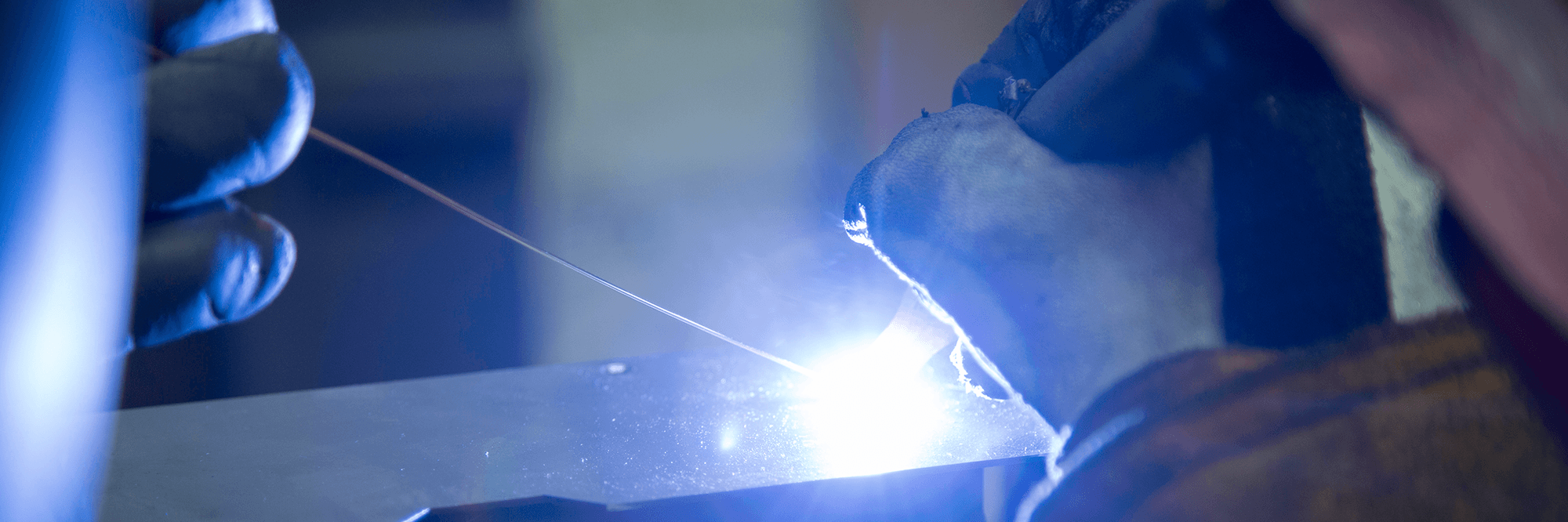

Welding

4 x Fully extracted welding units capable of T.I.G. and M.I.G

4 x Fettling stations with extraction

1 x Airbench Vertex walk-in modular extraction system for welding and cleaning

Forming

1 x Amada HG1003 ATC (Auto Tool Changing machine)

4 x C.N.C Forming machines linked to 3D software

1 x Warco Bending Rollers

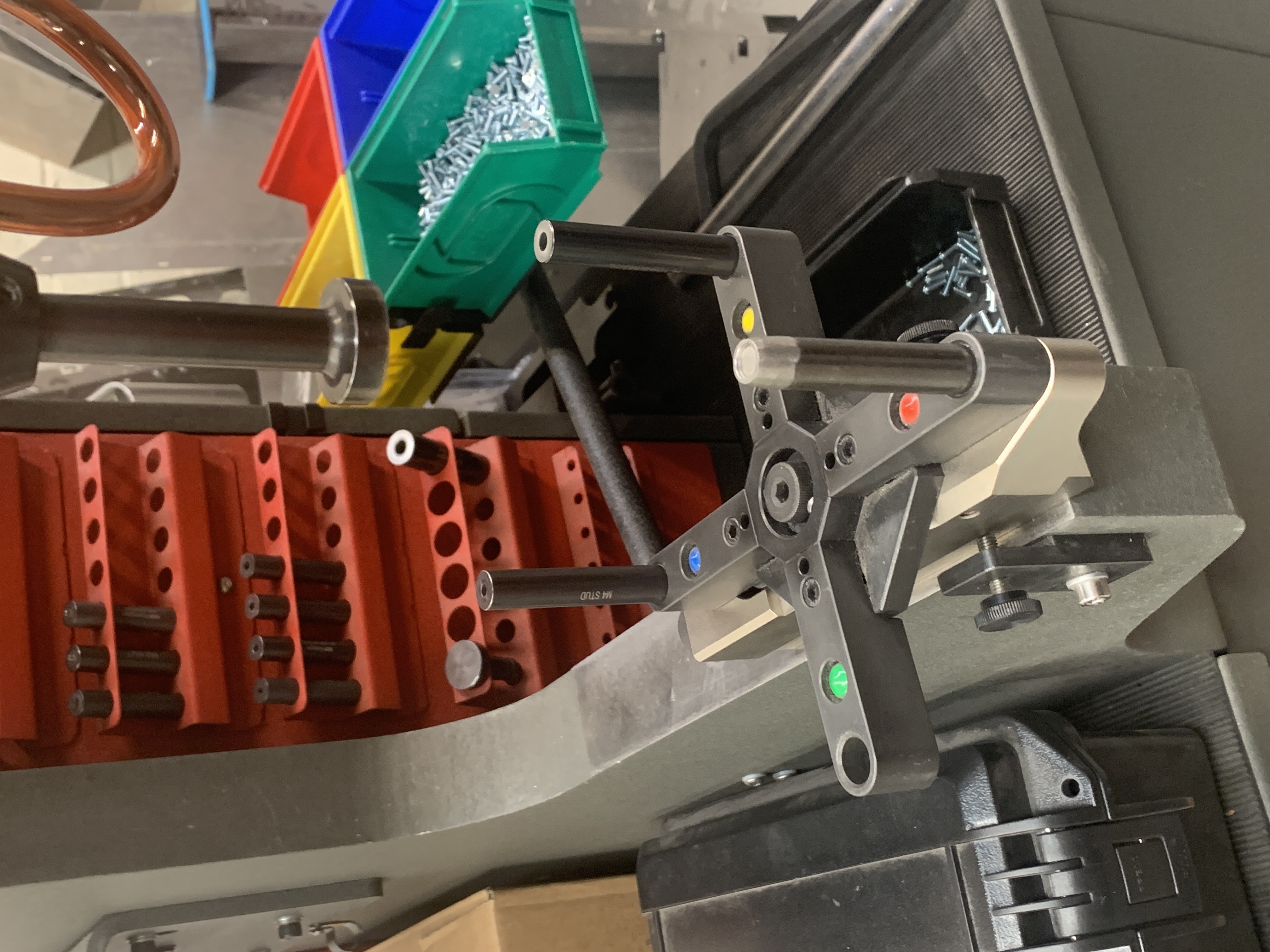

Bushing

4 x Haeger 6-Ton

Powder Coating

300ft Continuous Conveyor

3 Stage Degrease and Iron Phosphate pre-treatment

Dry Off Oven

2 x Powder Coating Booths

2 x Automatic Reciprocators

4 x Vibratory Box Fed Guns

2 x Curing Ovens

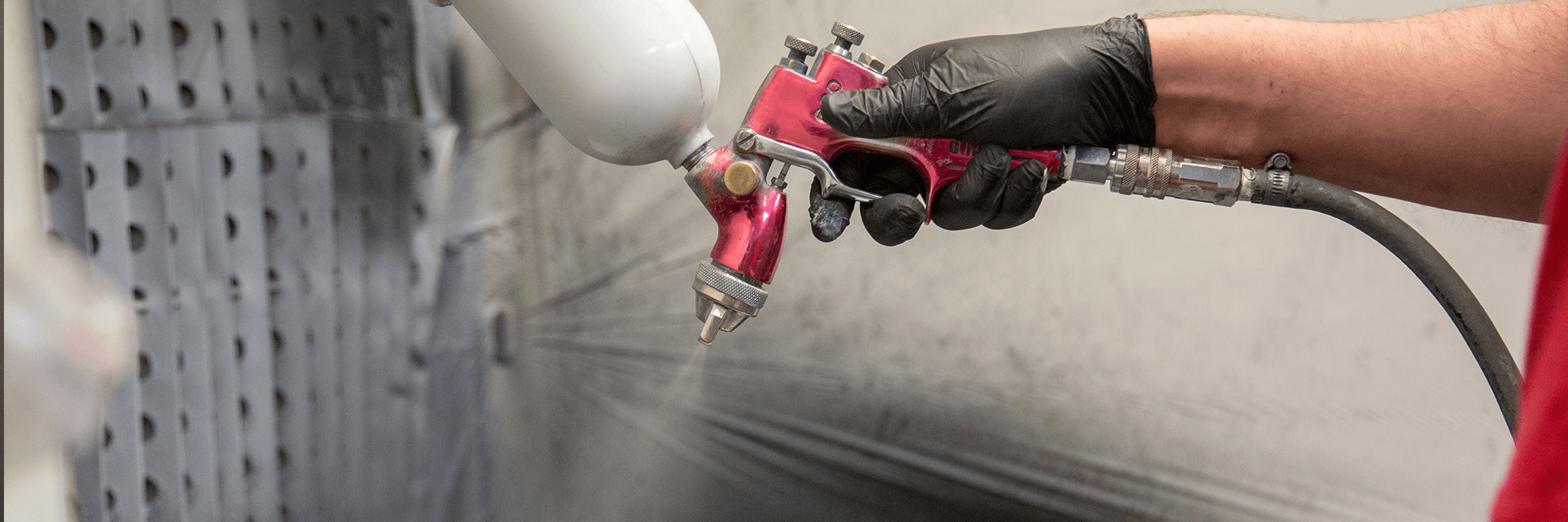

Wet Painting

Combined degrease and Iron Phosphate pre-treatment

1 x Spray Booths

1 x Curing Oven

Silkscreening

2 x Screen Printing Stations

Plating

Anodising

Black tin

Iridite NCP and Surtec 650

Nickel plating

Zinc and Clear, Colour

Assembly

Air-assisted rivet guns

Air-assisted power drivers

Avdel insertion guns

Drills

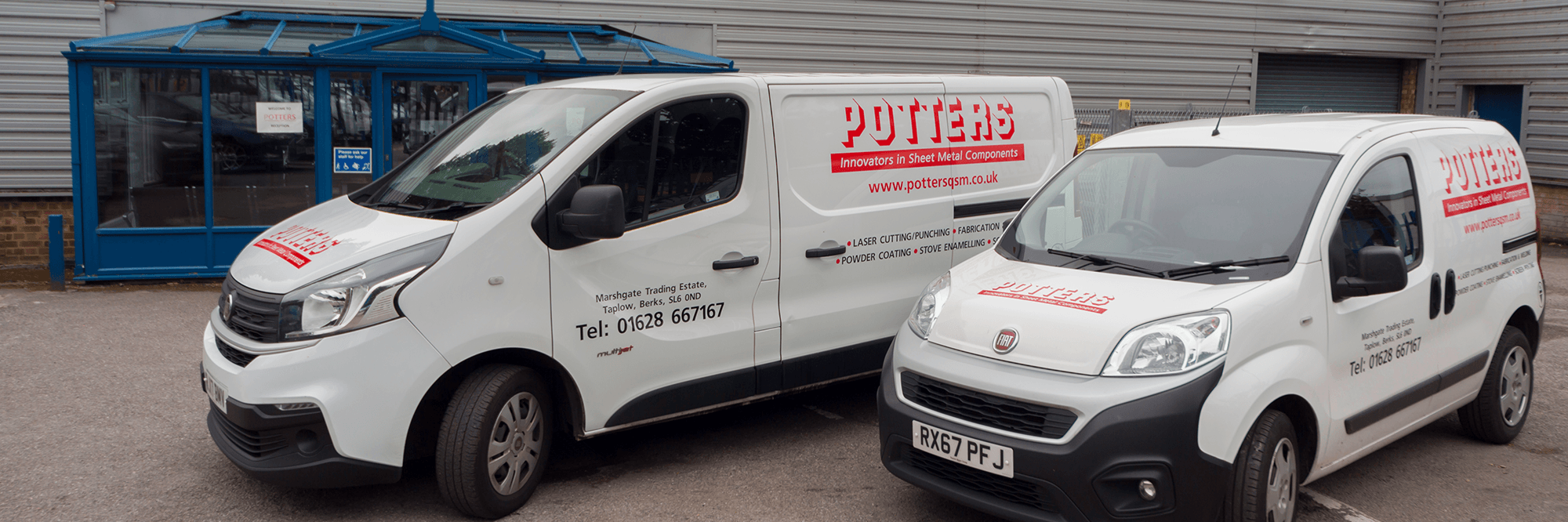

Packing and Delivery

Delivery via our own vehicles

Kanban and Stock call-off order systems

Enclosed Euro Bins

Loop Boxes

Packaging designed for specific products in volume

Customer unique labelling