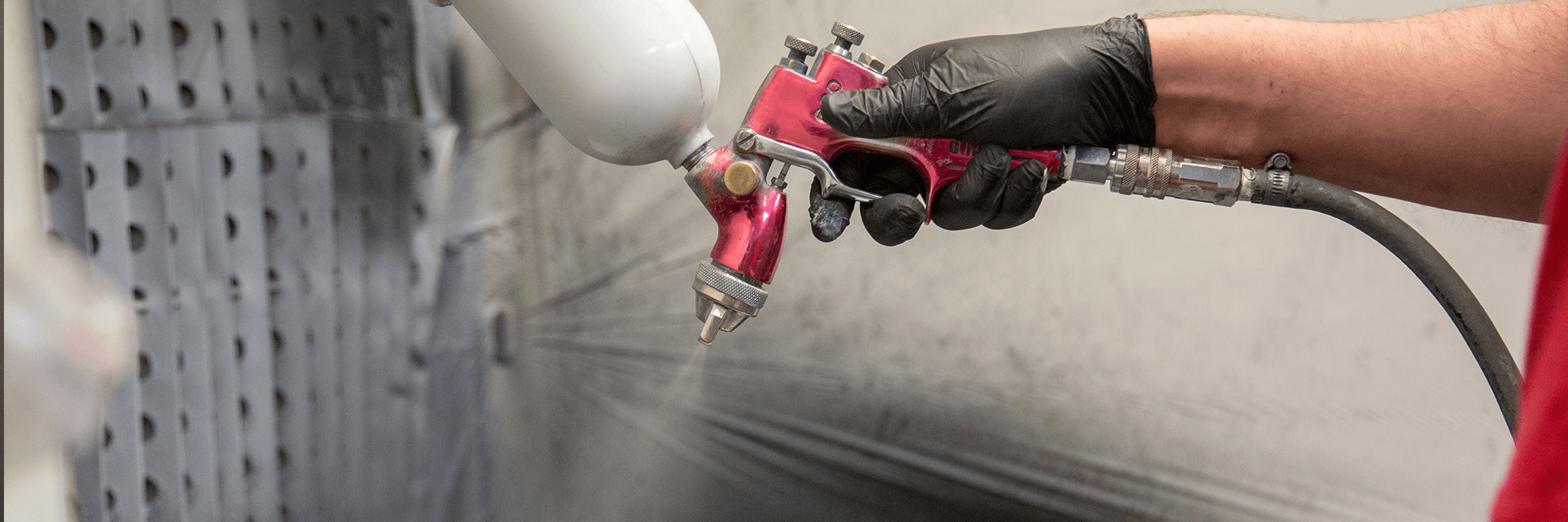

Experienced & Affordable Wet Painting Services

Our Stove Enamelling Service

If you are looking for a corrosion-resistant, and durable finish for your product, then wet painting is perfect. Otherwise known as stove enamelling, it’s a process in which specialist stoving paints are applied to a surface. That paint is then cured in an oven at a set temperature for a specific period. This strengthens the paint, giving you the strong and durable finish that you have been looking for.

Stove enamelling offers a much smoother finish than powder coating, and is typically used on metal components. When you work with us, we provide a wide range of colour options as well as a wide range of finishes. Wet spray painting has an excellent metal finish, offering a high-quality look and long-lasting corrosion protection.

Our wet painting metal finishes include heat-resistant paint for high-temperature surfaces. We also provide masking for earthing and RFI requirements and the filling of stud heads. This ensures excellent front panel quality for customer-facing components and control panels.

Successful application of wet spray painting is dependent on accuracy and consistency. We can provide both of these time after time. With years of stove-enamelling experience, we handle numerous applications daily on-site.

We prioritise detail and maintain clean spraying areas to prevent contamination. Our number one priority is your satisfaction. When completing jobs we’ll go out of our way to ensure a flawless finish.

If you would like to find out more about our wet painting services, please get in touch today. If you need help choosing the right paint for your specific application, that’s something that we can help with.

Wet Painting Technical Specifications

- Separate preparation and masking room

- Combined Degrease and Iron Phosphate Washing

- Spray booth

- Curing Oven

FAQ’s

What is stove enamelling?

Stove enamelling, also known as wet painting, is a process where specialist stoving paints are applied to a surface and then cured in an oven at a set temperature for a specific period. This strengthens the paint, creating a durable and corrosion-resistant finish.

What are the benefits of stove enamelling compared to powder coating?

Stove enamelling provides a much smoother finish than powder coating. It is ideal for metal components that require a high-quality appearance and long-lasting corrosion protection. Additionally, it offers a greater variety of colours and finishes, making it suitable for a wide range of applications.

What types of finishes do you offer?

We provide a wide range of colour options and finishes to suit different applications. Our wet painting metal finishes include heat-resistant coatings for high-temperature surfaces, as well as specialised masking for earthing and RFI requirements.

What materials can be coated with stove enamelling?

Stove enamelling is primarily used for metal components. This includes customer-facing components, control panels, and other industrial or commercial metal parts that require a strong, durable, and aesthetically pleasing finish.

How durable is the finish provided by stove enamelling?

The stove enamelling process results in a strong and durable coating that is resistant to corrosion and wear. The curing process in the oven enhances the strength of the paint, ensuring a long-lasting finish that can withstand various environmental conditions.